OUR CONSTRUCTION TECHNICS

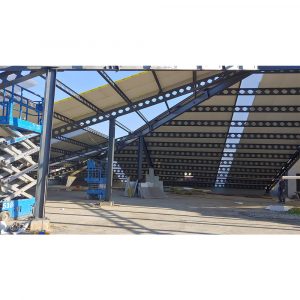

The carrier carcass is preferred as a composite system, enabling the construction and assembly of the building to be completed in a much shorter time. Together with that the build is much stronger and it will extend the service period.

Momentum Metal Construction adopts in principle to offer suitable servie, free of problems and reliable to its clients by using advanced technology in metal sector, hiring experienced employees and keeping requested servie well to the fore.

On behalf of senior management, Momentum Metal Construcion pledges to follow up developing technology in metal sector and to maintain our customer’s satisfation, business focus and employees at utmost level by strengthening our brand.

Momentum Metal Construcion’s management consists of experienced about sheet metal and metal market. The Company’s founders have practices in these metal products manufacturing industries over 45 years –and therest of the team consists of experienced managers, engineers, quality system managers, sales representatives, supervisors, skilled workers and so who worked im nay different majors along with their successful qualifications.

Why we prefer structural steel instead of light steel?

THE DIFFERENCES BETWEEN LIGHT STEEL & STRUCTURE STEEL

THE DIFFERENCES BETWEEN LIGHT STEEL & STRUCTURE STEEL

Moisture, which is one of the elements that is the steel enemy and determines the service life of the steel system, is usually of great importance in areas with high humidity. Light steel systems are manufatured from 0.7 to 1.8 mm thick galvanized sheets. The minumum thickness of the structure steel is 4.00 mm.

- All elements of light steel systems are formed by forming, cutting and drilling mounting holes of 0.7 to 1.8 mm thickness of galvanized steel according to project on CNC machines. The galvanized structure of the galvanized sheet is damaged during these operations. Therefore, especially at junctions, corrosion is beginning to occur and the already thin structure is thinned further and the lifetime of the structure is further shortened by reducing the resistance to external influences such as earthquakes and winds.

- Due to the frequent spacing of light steel profiles in the lightweight steel manufactured panels, the carrier system is damaged in forward modifications. Due to this, it is not possible to make any modifications such as additional windows, door openings, etc.

- Since light steel systems cannot carry heavy loads, they cannot be covered with heavy facade covering materials (stone, brick wall, etc.). Heavy-duty steel systems provide more flexibility in the choice of facade covering and insulation materials due to the higher load carrying capacities.

COMPOSITE FLOORING SYSTEM

COMPOSITE FLOORING SYSTEM

The roof system will be realized by pouring concrete on base concrete galvanized trapezoid sheet and steel wire reinforcement. This syste reduces the duration of mold assembly, standby and demolding of concrete pockets and workmanship to zero. This gain is valid for all horizontal and vertical conveying systems and removes mold cost and duration. Base concrete trapezium sheet also reduces the water loos of concrete compared to plywood molds and makes concrete maintenance easier.

WHY STEEL STRUCTURE?

- The quality of the steel structural elements is under constant supervision. It is produced in accordance with the standards and measurements in the factory conditions.

- As it is a homogeneous and isotropic material, it shows the expected behavior and the error in static calculations is very low.

- The working area of the building increases because of working with smaller sections.

- Wide openings, column-free cross-section with smaller cross-section possibility, provides great alternatives for the creation of large space and desired design at low cost.

- Much lighter structures can be built. This reduces the basic cost and provides a significant advantage against earthquake loads.

- It can be built very quickly in all weather conditions. This ensures low labor costs and quick response to needs.

- Qualified workmanship is required which this minimizes compliance errors.

- Material can be easily inspected at any time.

- Any damaged structural element can be replaced easily. This process is fast, easy and cost effective.

- Steel structure can be easily reinforced if desired; disassembly and reassembly, if desired.

- Steel construction elements can operate at full load capacity as soon as the assembly is completed.

DISADVANTAGE OF REINFORCED CONCRETE STRUCTURES

DISADVANTAGE OF REINFORCED CONCRETE STRUCTURES

- Technical and Material Differences Between Steel Structures and Reinforced Concrete Structures.

- Concrete quality may decrease in dangerous dimensions due to application errors.

- As it is not as homogeneous and isotropic as steel, the error margin is higher due to the assumptions in the static calculations (This error is considered in the project phase, which increases the cost).

- Significant losses occur in the area of use, even in minimal conditions requiring large cross sections.

- Does not require skilled labor.

- Important application errors may occur.

- Inspection of reinforced concrete steel after pouring concrete is very expensive and laborious.

- Reinforcing a damaged structural element for any reason is a difficult and costly process. This brings architectural problems.

- Cross sections are large and costs are higher in wide openings. The alternatives are more limited than steel structures in creating large spaces and desirable designs.

- Due to their large weight, the basic costs are also high. For the same reason, it is disadvantageous due to ground-ground interaction against earthquake loads.

- The construction period is long and it is not suitable for working in all weather conditions. Therefore, it provides longer term and higher cost solutions to the needy.

- Reinforcement of reinforced concrete structures is difficult. Also disassembly is not possible.

- Setting time of reinforced concrete structural elements is long for desired strength values.

ADVANTAGES of STEEL STRUCTURES OVER REINFORCED CONCRETE STRUCTURES

| Due to its flexibility, it is a more earthquake resistant construction system. | Achieving the same strength is much more costly and more risky due to excessive weight. |

| They are produced in standards and dimensions in accordance with the factory conditions. They exhibit self-expected and computable behaviors during an earthquake. The margin of error in static calculations is very low. | Since it is not as homogeneous and isotropic as steel, the error in static calculations is higher. Inspection of reinforced concrete steel after pouring concrete is very expensive and laborious. |

| Since there are no columns and beams, the area of use is more. Because of its high strength, it gives the designer the freedom to create wider spaces. | Even under minimal conditions, serious losses occur in the area of usage. Large cross-sections are required to cross wide openings, which is costly. |

| Its basic cost is lower because it is lighter. | Due to high weights, the basic costs are high and the ground-ground interaction against earthquake shocks is higher. |

| It is built in a shorter time, allows working in all kinds of weather conditions, materials are not damaged by water. This reduces labor and time costs. | Construction time is long and not suitable for all weather conditions. Therefore, it provides long-term and more cost-effective solutions. |

| It requires know-how and skilled workmanship. The error rate is lower as the labor force in production should be educated. | It does not require qualified workmanship, therefore, application error, work accident etc. rates are higher. |

| It is easy to control, there is no risk of stealing from the material as it is not hidden in the concrete. | The deviations in iron and concrete quality are much higher due to application errors in reinforced concrete structures. |

| After natural disaster situations, repair and maintenance is faster and less costly than reinforced concrete. | The deviations in iron and concrete quality are much higher due to application errors in reinforced concrete structures. |

| It can be used at full capacity as soon as the assembly process is finished. | The setting time is long for the desired strength values. |